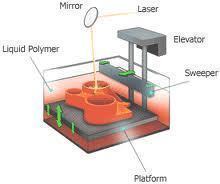

Stereolithography is a recently discovered process by which products, especially prototypes, can be constructed one layer at a time by using UV-curable photopolymer resins and a UV laser. While stereolithography cannot create every type of material, it produces a wide variety of products for testing, analysis, or review. Stereolithography can be used for a wide variety of applications and is most widely used to produce prototypes for the 3D printing industry.

How Stereolithography Works

Stereolithography is a complex process that requires a vat of liquefied, UV-curable photopolymer resins. A UV laser is used to trace over these resins in order to cure and solidify them and to produce patterns for specific product needs. Once the first layer is constructed, a fresh layer of resin is poured onto the first layer and the process is repeated. In addition to curing the resins, the UV laser also adheres each layer of resin to the layer below it. Once the product has been completely assembled, it is placed in a chemical bath to remove all traces of uncured resin and is then placed in a UV oven to completely cure the product.

Applications

Stereolithography is most widely used to produce prototypes that would take longer to create and cost more to produce if traditional manufacturing techniques were used. Stereolithography produces functional parts in a short amount of time so that they can be reviewed for advantages and disadvantages, ergonomics, and other specifications before they are mass produced on an assembly line. Stereolithography is also used for cast molding to make primary molds and doctors, scientists, and other biomedical engineers can use it to produce patient, implant, or organ molds.

Advantages

Stereolithography produces functional parts in a very short amount of time, usually less than one day. Stereolithography does not have any limitations on the shape of the product being produced and only the stereolithography machine’s physical attributes limits a product’s size.

Disadvantages

Stereolithography is extremely expensive. In fact, the photocurable resin that is used in stereolithography cost between $300 and $800 per gallon and stereolithography machines cost between $100,000 and $500,000, depending on the size and quality of the machine.

Follow Us!