Photolithography is the process of making integrated circuits through optical erosion. Rather than directly cutting into an integrated circuit, photolithography is used due to its ability to perform more precise incisions. Photolithography is a highly complex technique and requires both an extremely clean substrate surface and ideal temperature conditions. It can only be used to produce flat surfaces. Despite this, photolithography is the most popular technique used to make integrated circuits.

How Photolithography Works

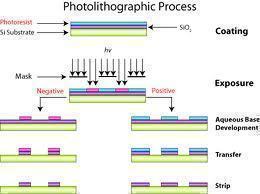

Photolithography begins with a substrate that has been previously cleaned with water or a chemical and has been purged of all liquids and contaminants. The substrate is then coated with a light-sensitive chemical and exposed to a focused beam of ultraviolet light. The ultraviolet light causes the exposed areas of the substrate to dissolve and a pattern is created. This pattern can then be used to transfer an electrical current from one side of the substrate to the other.

Applications

Photolithography produces integrated circuits and other internal computer parts. It has been used in recent years to produce nanites as well as microscopic computer systems. Photolithography also produces patterns on any small surface and is simply a form of lithography. Other forms of lithography include electron beam, X-ray, extreme ultraviolet, ion projection, and immersion lithography.

Advantages

Photolithography can etch a pattern into an integrated circuit with a single beam of ultraviolet light and does not require any additional materials. This allows photolithography to be highly efficient and cost-effective while producing extremely small incisions in a substrate. Also, photolithography controls the exact size and shape of the entire substrate.

Disadvantages

Photolithography requires a completely flat substrate in order to produce effective patterns. It is not efficient at producing objects that are not flat. Photolithography requires extremely clean conditions that are void of all contaminants, liquids, and environmental hazards.

Follow Us!